Precision CNC Machining Services: The Key to High-Quality Manufacturing

In today’s fast-paced manufacturing world, precision is critical. From aerospace components to automotive parts, medical devices, and intricate electronics, the need for highly accurate and reliable parts is more important than ever. This is where precision CNC (Computer Numerical Control) machining comes into play.

What is Precision CNC Machining?

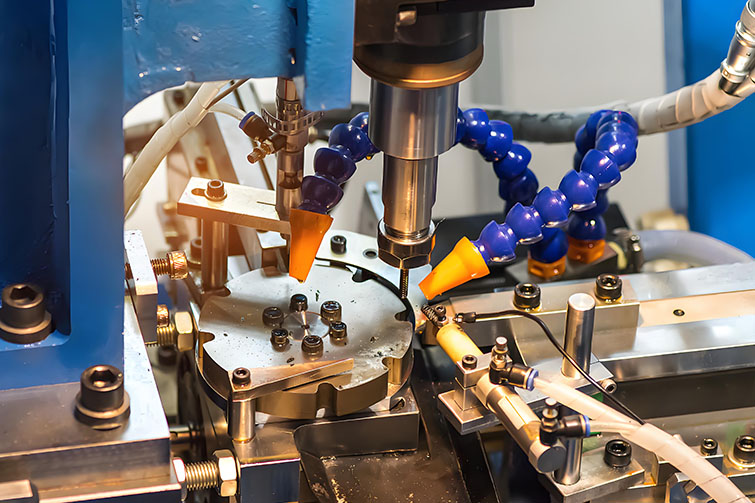

CNC machining refers to a process where a computer-controlled machine tool is used to remove material from a workpiece, typically metal or plastic, to create a desired part or product. Precision CNC machining involves the use of advanced techniques and high-accuracy machines to produce parts with very tight tolerances — sometimes as small as a few microns.

The precision aspect of this process makes it ideal for industries where even the smallest deviation can cause catastrophic failure, such as aerospace, medical, and automotive industries.

Key Features of Precision CNC Machining

- High Accuracy and Tolerance: Precision CNC machining allows for the production of parts with exceptional accuracy, often up to +/-0.005mm or even tighter. This high level of precision ensures that every component fits together perfectly, reducing the risk of failure and improving the overall performance of the final product.

- Complex Geometries: CNC machines can handle complex geometries and intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods. Whether it's an elaborate surface finish or a multi-dimensional part, CNC machining can handle it all.

- Efficiency and Speed: Unlike manual machining, CNC machines can work at a much faster rate, leading to reduced production time. The automation of the machining process ensures that the same high level of precision can be maintained throughout the entire production run, no matter the number of parts.

- Material Versatility: Precision CNC machines can work with a wide range of materials including metals like aluminum, titanium, stainless steel, and alloys, as well as plastics such as nylon and polycarbonate. This versatility makes CNC machining an essential service across various industries.

Applications of Precision CNC Machining

- Aerospace: The aerospace industry requires parts that are not only strong and durable but also lightweight. CNC machining allows for the creation of complex, high-performance components like turbine blades, engine mounts, and landing gear with extreme precision.

- Medical Devices: The medical industry relies on parts with strict tolerances, such as implants, surgical instruments, and diagnostic equipment. Precision CNC machining ensures that these components meet stringent quality standards and perform reliably.

- Automotive: Automotive manufacturers require precision parts for engines, transmissions, and suspension systems. CNC machining enables the production of custom parts and prototypes, as well as high-volume production runs, all with the utmost accuracy.

- Electronics: In the electronics sector, precision machining is used to create intricate housings, connectors, and other small components that require precise tolerances to ensure proper functionality.

Benefits of Using Precision CNC Machining Services

- Cost-Effective for High-Volume Production: Though the initial setup costs for CNC machining can be higher, the long-term benefits of high-speed production, fewer errors, and minimal waste make it cost-effective, especially for large-scale manufacturing.

- Customization: Whether you need a one-off prototype or a high-volume run, CNC machining offers the flexibility to create custom parts to meet specific design requirements, reducing the need for expensive tooling or assembly.

- Consistency: CNC machines can produce parts with the same level of precision, time and time again. This level of consistency ensures that each part in a batch will meet the same high standards, helping businesses maintain quality control.

- Reduced Waste: CNC machining is highly efficient, which reduces material waste. The precise cutting processes mean less excess material is removed, making the entire manufacturing process more sustainable and cost-effective.

Conclusion

Precision CNC machining has revolutionized the way manufacturers produce high-precision components, providing industries with a reliable and cost-effective solution to meet the demands of modern production. Whether you're in the aerospace, automotive, medical, or electronics industry, precision CNC machining can ensure that your products are produced with the highest level of accuracy, efficiency, and quality.

By leveraging this technology, manufacturers can not only improve their product performance but also reduce production costs and meet tight deadlines, ensuring they stay competitive in an increasingly demanding global market.