Bearing, Grinding, and Centerless Grinding Services: Precision for Critical Applications

In industries that require high-performance machinery and components, bearings, grinding, and centerless grinding play essential roles in ensuring smooth operation, durability, and precision. These services are used in various applications ranging from automotive to aerospace, industrial machinery, and medical devices. Let’s take a closer look at these services and how they contribute to modern manufacturing.

1. Bearing Services: Essential for Smooth Motion

Bearings are integral to the smooth operation of machines by reducing friction between moving parts. They allow for the free rotation or linear movement of components while minimizing wear and tear. Bearings come in various forms, including ball bearings, roller bearings, and needle bearings, each designed to handle different loads, speeds, and applications.

Bearing Services typically include:

- Manufacturing and Customization: Bearings can be made from a variety of materials such as steel, ceramic, or plastic. Precision bearing services ensure that the bearings are created with exact tolerances to fit the specific application.

- Inspection and Testing: To ensure quality and performance, bearings undergo rigorous testing to measure their load-bearing capacity, durability, and friction properties. This helps identify any defects or weaknesses before the bearings are used in critical machinery.

- Maintenance and Repair: Regular maintenance of bearings, such as lubrication or cleaning, can prevent premature failure. Bearing services also include repairs and replacements to keep machinery running smoothly.

- Assembly and Integration: Precision bearing services involve integrating the bearings into machinery, ensuring that they are properly installed and aligned for optimal performance.

Applications:

- Automotive: Bearings are used in engines, wheels, transmissions, and other moving parts of vehicles.

- Aerospace: Bearings are essential for aircraft engines, landing gear, and control systems.

- Industrial Machinery: Bearings help reduce friction in conveyor systems, pumps, motors, and more.

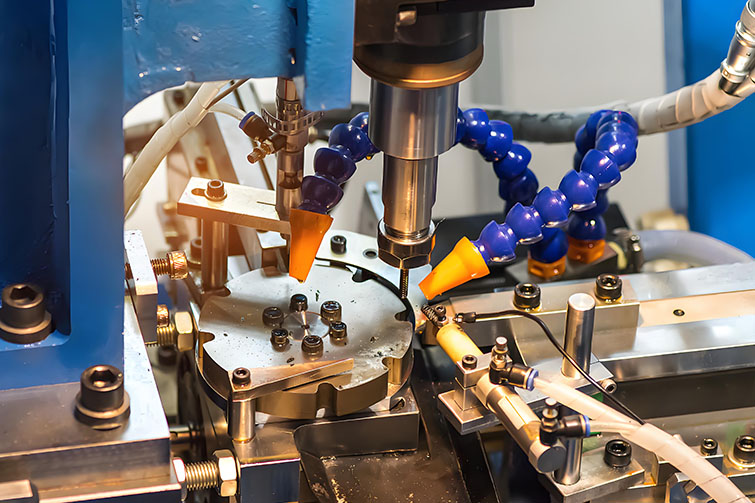

2. Grinding Services: Achieving Superior Surface Quality

Grinding is a machining process used to remove material from a workpiece to achieve a high level of surface finish and dimensional accuracy. The grinding process can be used on a wide range of materials, including metals, ceramics, and plastics. It typically uses an abrasive wheel to smooth the surface and improve precision.

Grinding services include:

- Surface Grinding: This type of grinding produces flat surfaces with a smooth finish, often used for parts that require precise dimensional control, such as plates, blocks, and tool components.

- Cylindrical Grinding: Used for grinding cylindrical parts like shafts and rods, this service ensures that the parts are accurately sized, round, and have the required surface finish.

- Internal Grinding: Internal grinding involves grinding the inner diameter of a workpiece, such as the inside of a pipe or tube, to achieve smoothness and accuracy in internal features.

- Angle and Form Grinding: For parts that require angular or specific shapes, form grinding allows for precise profiles, including beveled, contoured, and threaded surfaces.

Benefits of Grinding Services:

- High Precision and Accuracy: Grinding is capable of achieving extremely tight tolerances and superior surface finishes (sometimes down to micro-level precision).

- Versatility: Grinding can be applied to a variety of materials and shapes, making it suitable for both prototype and high-volume production runs.

- Improved Surface Integrity: Grinding not only improves dimensional accuracy but also enhances surface finish and reduces roughness, which can be critical for high-performance applications.

Applications:

- Tool Manufacturing: Grinding services are essential for producing cutting tools like drills, end mills, and inserts.

- Aerospace: In aerospace, grinding is used for precision components such as turbine blades, gears, and critical engine parts.

- Automotive: Grinding is used for producing highly precise components, including camshafts, crankshafts, and pistons.

3. Centerless Grinding Services: Efficiency and Precision for Long Parts

Centerless grinding is a specialized form of grinding that involves a workpiece being supported by a set of rollers and a grinding wheel, with no need for a center hole or chucking. This method is ideal for high-volume production of long, cylindrical parts, where traditional grinding methods may be inefficient.

The centerless grinding process involves two main types:

- Through-feed Centerless Grinding: Used for parts that are fed continuously through the grinding machine. This is typically used for producing long, cylindrical components like rods, tubes, and shafts.

- In-feed Centerless Grinding: Suitable for parts that need to be ground with varying diameters or specific shapes, where the part is fed into the machine in one pass.

Benefits of Centerless Grinding:

- High Production Efficiency: Because parts can be continuously fed through the machine, centerless grinding is highly efficient for mass production of long cylindrical parts.

- Precision and Consistency: Centerless grinding provides exceptional dimensional accuracy, even for large production runs, ensuring each part is identical.

- Cost-Effectiveness: Centerless grinding minimizes the need for fixturing and clamping, making it more cost-effective compared to traditional grinding methods.

Applications:

- Automotive Industry: Centerless grinding is used for high-precision components such as shafts, pins, and rollers in automotive engines, gear systems, and transmissions.

- Medical Devices: Components like surgical instruments, implants, and precision tubes often require centerless grinding to achieve tight tolerances.

- Aerospace: Centerless grinding is used for producing parts like hydraulic components, valves, and small bearings.

Conclusion: Precision Services for Critical Industries

Bearing, grinding, and centerless grinding services are critical for producing high-performance components that meet the strict standards of industries such as automotive, aerospace, medical devices, and industrial machinery. These services ensure that components function smoothly, have long lifespans, and operate with minimal wear and tear. Whether it's for reducing friction in bearings, achieving a perfect surface finish in grinding, or producing highly accurate cylindrical parts in centerless grinding, these precision services contribute to the reliability and efficiency of modern technology.

By investing in these specialized machining services, manufacturers can ensure that their components meet the highest quality standards, leading to enhanced performance, reduced downtime, and lower operational costs.