1. Basic Machining: The forged steel/aluminum alloy blanks are first cut to size, then the six external surfaces are milled. Rough and fine grinding are then performed to ensure flatness and perpendicularity. 2. Hole Machining: Oil passages and mounting holes are machined using drilling/boring. Deep holes are machined using gun drilling/BTA deep hole drilling technology; threaded holes are formed by tapping/thread milling. 3. Post-processing: The parts are deburred, high-pressure cleaned, and then subjected to surface anti-corrosion treatment (such as nickel plating or bluing). Finally, a pressure test is performed to verify the sealing performance.

Hydraulic Valve Block Machining Process Steps List

1. Raw Material Preparation

◦ Select suitable materials (e.g., carbon steel, stainless steel, aluminum alloy) according to working pressure and medium requirements.

◦ Cut the raw material into blanks of specified size by sawing or flame cutting.

2. Blank Rough Machining

◦ Perform milling on the six sides of the blank to ensure basic flatness and perpendicularity, leaving a machining allowance of 0.5–1 mm for each surface.

◦ Remove oxide scale and burrs on the blank surface by grinding or sandblasting.

3. Precision Machining of Reference Surfaces

◦ Grind the reference surfaces (usually three mutually perpendicular surfaces) to meet the flatness tolerance of ≤0.02 mm and perpendicularity tolerance of ≤0.01 mm.

◦ Mark the machining coordinate origin based on the reference surfaces for subsequent CNC machining positioning.

4. CNC Drilling & Boring

◦ Use CNC machining center to drill oil passages, mounting holes, and pin holes with twist drills or deep hole drills (for holes with length-diameter ratio >10).

◦ Bore the main valve mounting holes and high-precision matching holes to achieve a hole diameter tolerance of H7/H8 and surface roughness Ra≤1.6 μm.

5. Thread Machining

◦ Process internal threads of mounting holes and oil port connections by tapping

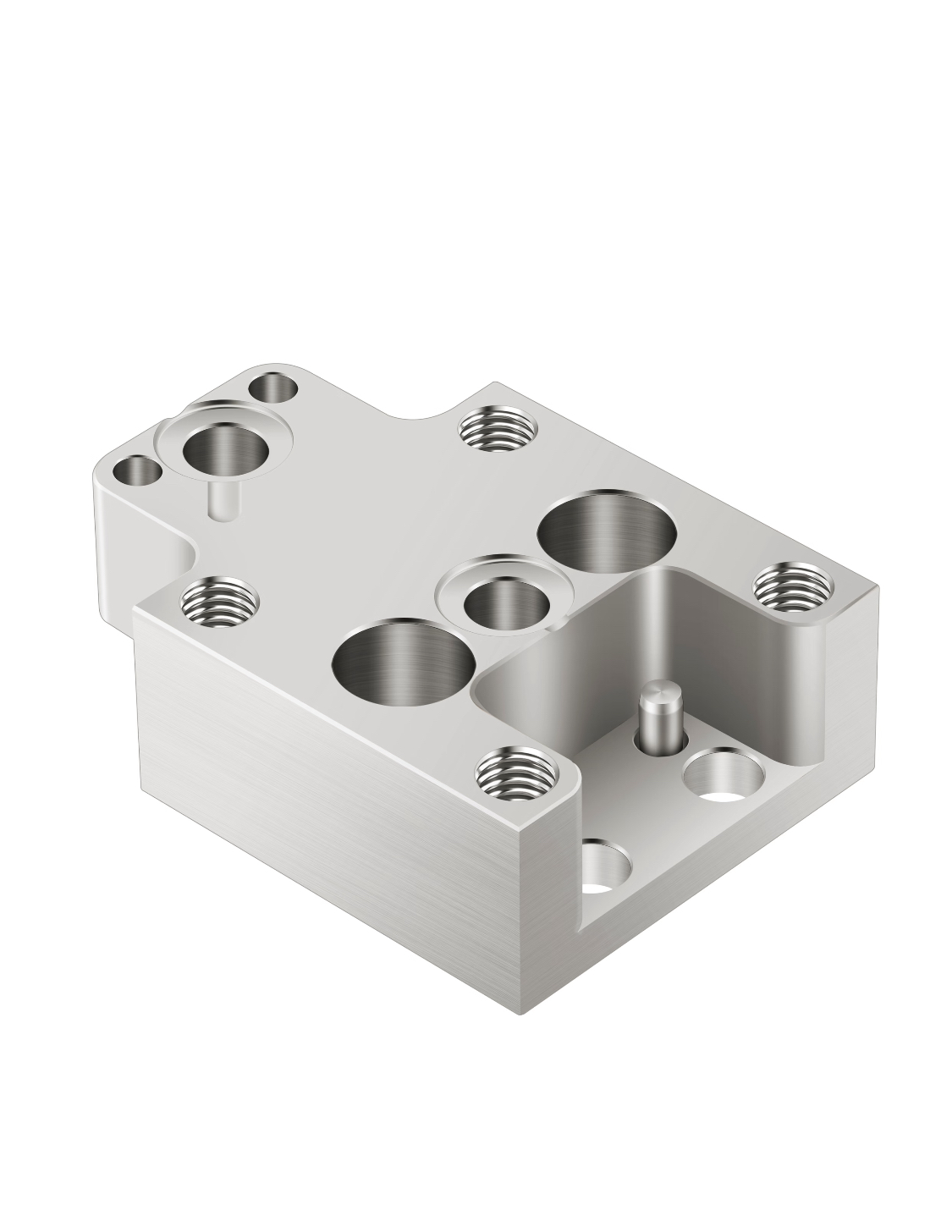

This precision-machined aluminum alloy component is a custom non-standard structural part engineered for high-precision industrial applications such as automated production lines, precision machinery fixtures, and equipment positioning systems. Fabricated from premium aerospace-grade aluminum alloys (6061/7075), it integrates intricate features including milled cavities, threaded holes, counterbores, and locating pins, delivering exceptional dimensional accuracy (tolerance within ±0.005mm) and structural stability. Designed to fulfill critical functions of positioning, mounting, and connection in complex mechanical systems, it offers lightweight performance combined with high strength and corrosion resistance.

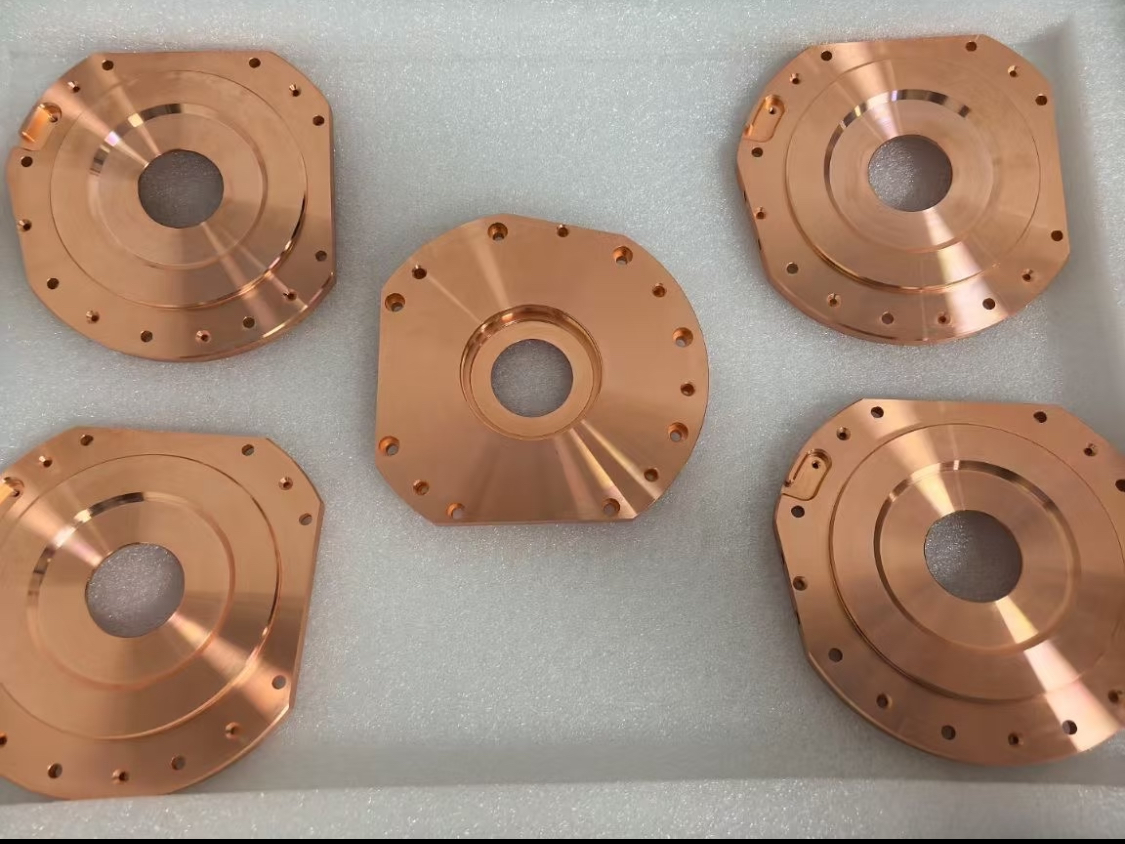

This product is a purple copper precision mechanical part (also known as red copper CNC machined parts), which belongs to high-precision mechanical components.