For high-volume orders with exacting criteria, we use multi-spindle CNC and Cam machines that can handle complex, challenging parts at a faster rate than single-spindle machines.

Davenport, a leader in US-based multi-spindle machining

New Britain

Tornos

Index

Precision parts with up to 2" (51mm) outside diameter

Polygonal Turning

Knurling/Threading

Cross Drilling

CNC machining with a variety of materials

including: Brasses, stainless steels, plastics and more

High volume machining

Precision parts with a max OD (Round) .875”

Precision parts with a max OD (Hex) .750

Precision parts with max Length 4”

Precision parts with a standard tolerance +/- .001 with capability up to +/-.0006”

CNC machining with a variety of materials including Brasses, stainless steels, steels, plastics, and more

High Surface Finishing AvailableWe offer high surface finishing for parts that require a mirror-like finish.

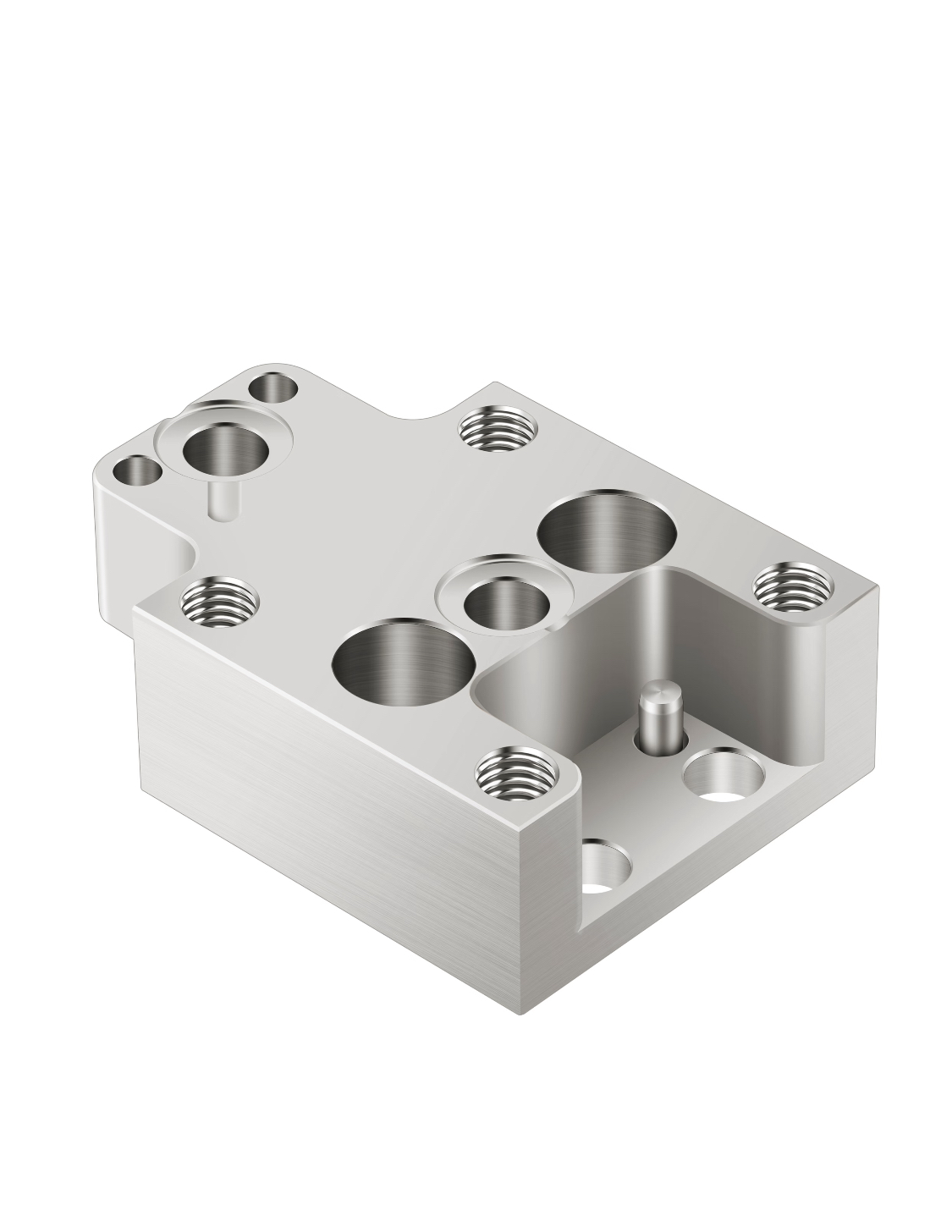

This precision-machined aluminum alloy component is a custom non-standard structural part engineered for high-precision industrial applications such as automated production lines, precision machinery fixtures, and equipment positioning systems. Fabricated from premium aerospace-grade aluminum alloys (6061/7075), it integrates intricate features including milled cavities, threaded holes, counterbores, and locating pins, delivering exceptional dimensional accuracy (tolerance within ±0.005mm) and structural stability. Designed to fulfill critical functions of positioning, mounting, and connection in complex mechanical systems, it offers lightweight performance combined with high strength and corrosion resistance.

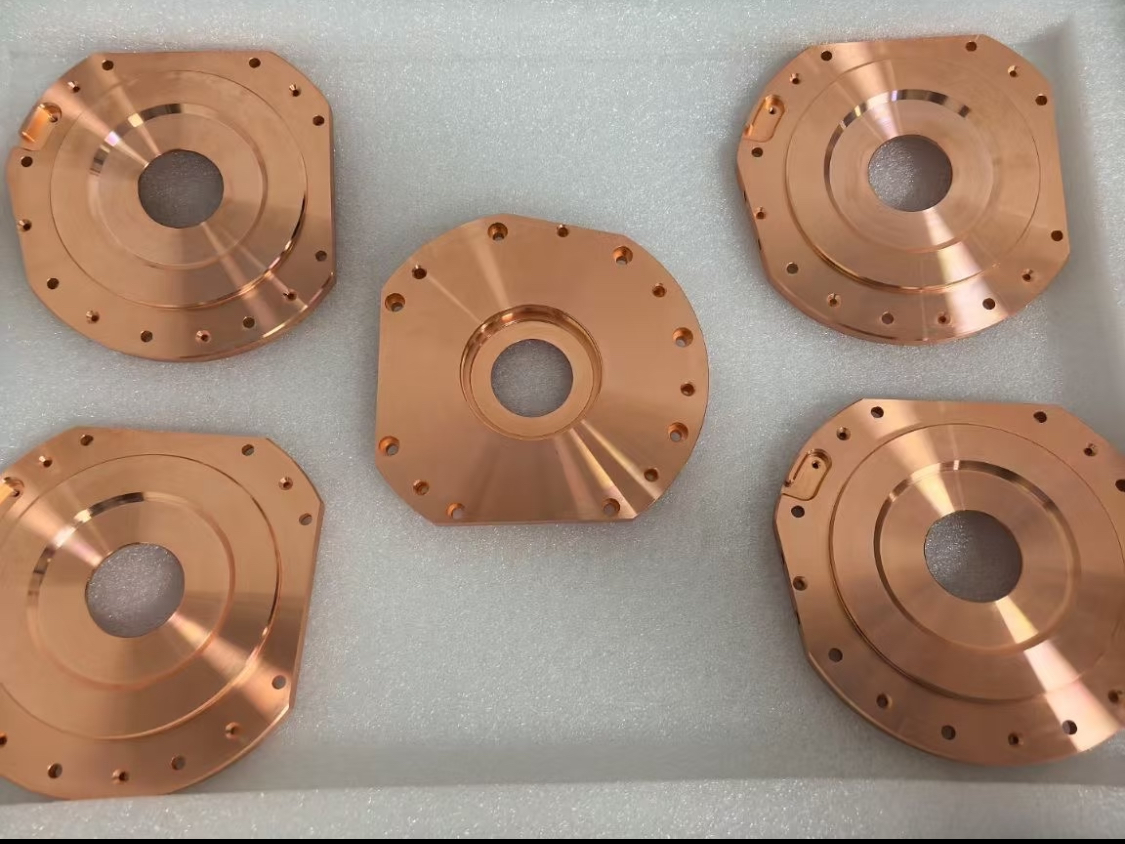

This product is a purple copper precision mechanical part (also known as red copper CNC machined parts), which belongs to high-precision mechanical components.

1. Basic Machining: The forged steel/aluminum alloy blanks are first cut to size, then the six external surfaces are milled. Rough and fine grinding are then performed to ensure flatness and perpendicularity. 2. Hole Machining: Oil passages and mounting holes are machined using drilling/boring. Deep holes are machined using gun drilling/BTA deep hole drilling technology; threaded holes are formed by tapping/thread milling. 3. Post-processing: The parts are deburred, high-pressure cleaned, and then subjected to surface anti-corrosion treatment (such as nickel plating or bluing). Finally, a pressure test is performed to verify the sealing performance.