This precision-machined aluminum alloy component is a custom non-standard structural part engineered for high-precision industrial applications such as automated production lines, precision machinery fixtures, and equipment positioning systems. Fabricated from premium aerospace-grade aluminum alloys (6061/7075), it integrates intricate features including milled cavities, threaded holes, counterbores, and locating pins, delivering exceptional dimensional accuracy (tolerance within ±0.005mm) and structural stability. Designed to fulfill critical functions of positioning, mounting, and connection in complex mechanical systems, it offers lightweight performance combined with high strength and corrosion resistance.

1. Material Superiority

Constructed from 6061 or 7075 aluminum alloy, the component benefits from the material’s high tensile strength, excellent machinability, and lightweight properties. 7075 alloy variants further provide enhanced hardness and fatigue resistance for heavy-duty applications, while 6061 alloy offers superior corrosion resistance and cost-effectiveness for general industrial use.

2. Precision Machining Process

• CNC Milling: Multi-axis CNC machining centers perform high-precision milling of cavities, contours, and flat surfaces, ensuring tight dimensional tolerances and smooth surface finishes (Ra ≤ 1.6μm).

• Drilling & Tapping: Computer-controlled drilling and tapping create accurately positioned threaded holes and counterbores, with thread precision meeting ISO 4H/5H standards for secure fastener engagement.

• Surface Finishing: Anodization (clear/color anodizing or hard anodizing) is applied to enhance corrosion resistance, wear resistance, and aesthetic appeal. Optional sandblasting or brushing processes further refine the surface texture for specific application requirements.

• Quality Verification: Coordinate Measuring Machine (CMM) and optical comparator inspections validate all critical dimensions, ensuring compliance with design specifications and industrial quality standards.

3. Application Scope

This component is widely utilized in automotive manufacturing fixtures, electronic equipment assembly jigs, aerospace component testing tools, and robotic automation systems. Its customizability allows it to be tailored to unique mechanical design requirements, making it a versatile solution for precision engineering across diverse industries.

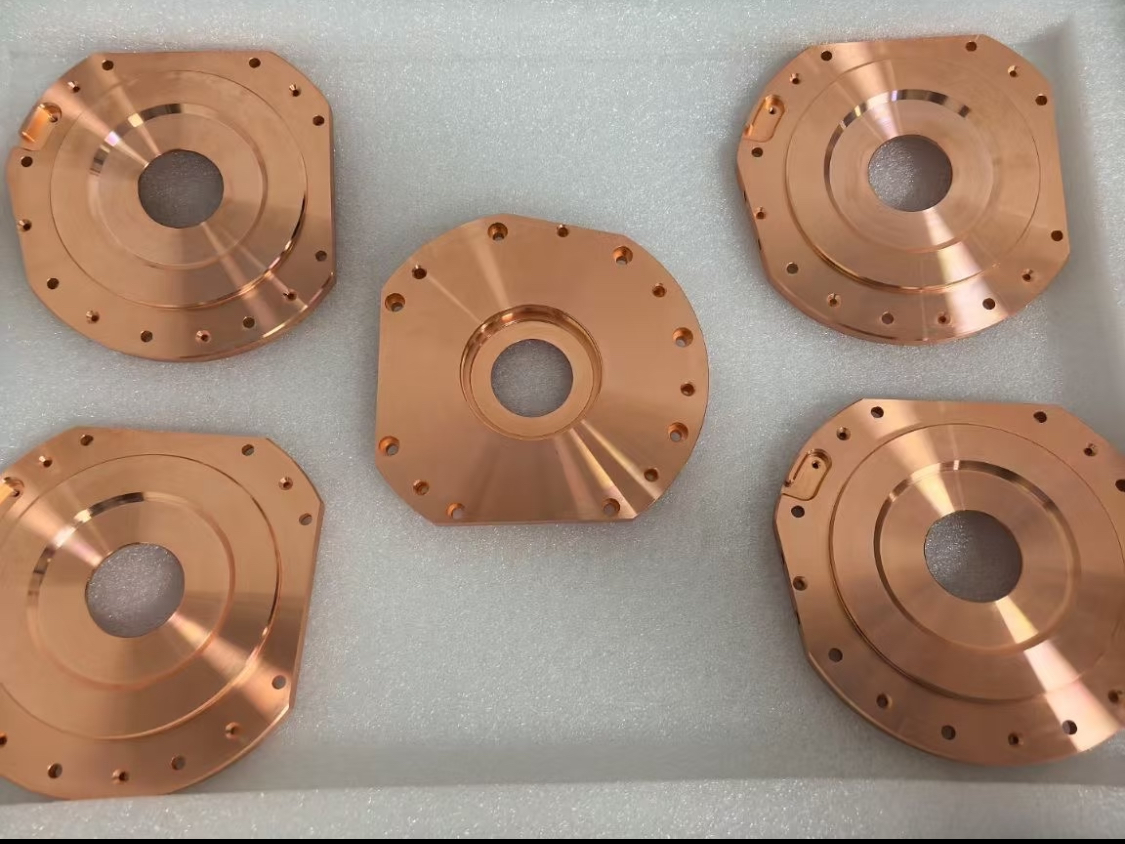

This product is a purple copper precision mechanical part (also known as red copper CNC machined parts), which belongs to high-precision mechanical components.

1. Basic Machining: The forged steel/aluminum alloy blanks are first cut to size, then the six external surfaces are milled. Rough and fine grinding are then performed to ensure flatness and perpendicularity. 2. Hole Machining: Oil passages and mounting holes are machined using drilling/boring. Deep holes are machined using gun drilling/BTA deep hole drilling technology; threaded holes are formed by tapping/thread milling. 3. Post-processing: The parts are deburred, high-pressure cleaned, and then subjected to surface anti-corrosion treatment (such as nickel plating or bluing). Finally, a pressure test is performed to verify the sealing performance.